Units for the measurements in the tables in mm. – Force equivalence (1Kg=10N).

Adhesion forces; determined at room temperature on polished steel plate (S235JR DIN 10025) thick 10 mm pulling the magnet vertically to the surface. A deviation of -10% in the values is possible exceptionally. In general, the value will be exceeded.

These rubber magnetic bases with neodymium magnets and coated with a special rubber, can be used on delicate metal surfaces (painted, chrome, nickel, etc.). Due to the consistency of this special rubber, these surfaces are protected against scratches, as long as the surfaces are already clean of dust and particles. Due to the high coefficient of lateral friction of this type of special rubber, these magnetic bases support very high efforts of STATIC FRICTION .

The rubber lining is black as standard. White colors are available for all models as standard. Optionally, the rubber can be pigmented in Blue, Red, Gray or Green.

This magnetic base has the particularity of being multipolar in the most powerful models of pot magnets with rubber coating.

| Item code | D | H | L | d | M | g-weight | Force N | Friction N* |

| 04.A12AKSM4 | 12 | 7 | 14.5 | Q | M4 | 6 | 13 | 5 |

| 04.A18AKSM4 | 18 | 6 | 11.5 | 8 | M4 | 8.7 | 37 | 13 |

| 04.A22AKSM4 | 22 | 6 | 11.5 | 8 | M4 | 13 | 58 | 18 |

| 04.A31AKSM4 | 31 | 6 | 11.5 | 8 | M4 | 22 | 89 | 25 |

| 04.A31AKSM4S | 31 | 6 | 11.5 | 8 | M4 | 23 | 89 | 35 |

| 04.A43AKSM4 | 43 | 6 | 10.5 | 8 | M4 | 30 | 100 | 30 |

| 04.A43AKSM5 | 43 | 6 | 10.5 | 8 | M5 | 31 | 100 | 30 |

| 04.A57AKSM5* | 57 | 6 | 14.5 | 10 | M5 | 82 | 200 | 78 |

| 04.A66AKSM5* | 66 | 8.5 | 15 | 10 | M5 | 105 | 250 | 85 |

| 04.A88AKSM8* | 88 | 8.5 | 17 | 12 | M8 | 190 | 550 | 140 |

| * Up to 80ºC | ||||||||

| Item code | D | H | L | M | g-weight | Force N | Friction N* |

| 04.A12AGKSM4X8 | 12 | 7 | 15.5 | M4X8 | 4.5 | 13 | 5 |

| 04.A18AGKSM4X6 | 18 | 6 | 12 | M4X6 | 7.6 | 37 | 13 |

| 04.A22AGKSM4X6 | 22 | 6 | 12.5 | M4X6.5 | eleven | 58 | 18 |

| 04.A31AGKSM6X11 | 31 | 6 | 17 | M6X11 | 24 | 89 | 35 |

| 04.A43AGKSM4X6 | 43 | 6 | 12 | M4X6 | 30 | 100 | 38 |

| 04.A43AGKSM6X15T* | 43 | 6 | 21 | M6X15 | 32 | 100 | 38 |

| 04.A57AGKSM6X15* | 57 | 7.6 | 22.6 | M6X15 | 77 | 200 | 78 |

| 04.A66AGKSM8X15* | 66 | 8.5 | 23.5 | M8X15 | 107 | 250 | 85 |

| 04.A88AGKSM8X15* | 88 | 8.5 | 23.5 | M8X15 | 193 | 550 | 140 |

| *Up to 80ºC | |||||||

| Item code | D | H | M | g-weight | Force N | Friction N* |

| 04.A18DKSM4 | 18 | 6 | M4 | 6 | 25 | 8 |

| 04.A22DKSM4 | 22 | 6 | M4 | 9 | 38 | 15 |

| 04.A31DKSM5 | 31 | 6 | M5 | 21 | 89 | 25 |

| 04.A31DKSM5 | 31 | 6 | M5 | 22 | 89 | 35 |

| 04.A43DKSM4 | 43 | 6 | M4 | 29 | 100 | 38 |

| 04.A57DKSM5* | 57 | 7.6 | M5 | 79 | 200 | 78 |

| 04.A66DKSM6* | 66 | 8.5 | M6 | 100 | 250 | 85 |

| 04.A88DKSM6* | 88 | 8.5 | M6 | 186 | 550 | 140 |

| *Up to 80ºC | ||||||

| Item code | D | H | M | g-weight | Force N | Friction N* |

| 04.A18DKSM4S | 18 | 13 | 4 | 7 | 25 | 8 |

| 04.A22DKSM4S | 26 | 16 | 4 | 12 | 38 | 15 |

| 04.A31DKSM5S | 31 | 16 | 5 | 26 | 89 | 19 |

| 04.A43DKSM4S | 43 | 16 | 4 | 30 | 100 | 38 |

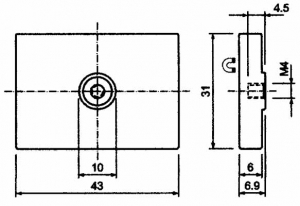

| Item code | W | H | L | M | g-weight | Force N | N* | Friction N** |

|---|---|---|---|---|---|---|---|---|

| 04.A43X31AKSM4* | 43 | 6 | 31 | M4X4.5 | 27 | 105 | / | 38 |

| 04.A43X31AKS2M4** | 43 | 6 | 31 | 2XM4X4.5 | 28 | 146 | / | 38 |

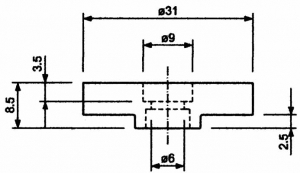

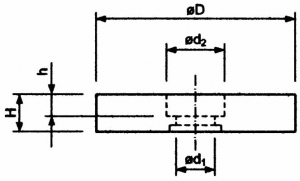

| Item code | D | H | h | d1 | d2 | g-weight | Force N | Friction N* |

| 04.A18CKS | 18 | 6 | 3.5 | 3 | 8.2 | 5.5 | 25 | 8 |

| 04.A22CKS | 22 | 6 | 3.5 | 4 | 8.2 | 8 | 38 | 15 |

| 04.A31CKS | 31 | 6 | 3.5 | 6 | 9 | 20 | 89 | 25 |

| 04.A31CKSA | 31 | 8.5 | 3.5 | 6 | 9 | 20 | 89 | 25 |

| 04.A57CKS | 57 | 7.6 | 3.3 | 8 | 25 | 77 | 200 | 78 |

| 04.A66CKs* | 66 | 8.5 | 3.2 | 5.5 | 22 | 100 | 250 | 85 |

| Up to 80ºC | ||||||||

| Item code | D | d1 | d2 | H | Temp. | g-weight | Force N | Friction N* |

| 04.A43CK-AV | 43 | 7.5 | 12.8 | 6 | 60ºC | 27 | 100 | 38 |

| 04.A88CK-AV | 88 | 6.6 | 12 | 8.5 | 80ºC | 182 | 550 | 140 |

Recent Comments