Qualities and types of ferrite magnetic bases

Units for the measurements in the tables in mm. – Force equivalence (1Kg=10N).

Adhesion forces; determined at room temperature on polished steel plate (S235JR DIN 10025) thick 10 mm pulling the magnet vertically to the surface. A deviation of -10% in the values is possible exceptionally. In general, the value will be exceeded.

Ferrite or ceramic magnetic bases

These magnetic bases are made with ferrite or ceramic magnets. They are protected by a metal casing that provides greater safety at work and prevents their breakage. They are ideal for any application of assembly, machining and/or fixing of parts.

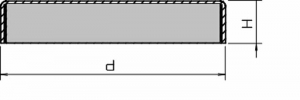

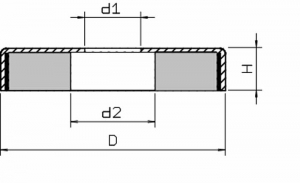

| Item code | D | H | g-weight | Force N | Force Kg |

| 4,801 | 10 | 4.5 | 2 | 4 | 0.4 |

| 4,802 | 13 | 4.5 | 3 | 10 | 1 |

| 4,803 | 16 | 4.5 | 5 | 18 | 1.8 |

| 4,804 | 20 | 6 | 10 | 30 | 3 |

| 4,805 | 25 | 7 | 18 | 40 | 4 |

| 4,806 | 32 | 7 | 29 | 80 | 8 |

| 4,807 | 40 | 8 | 55 | 125 | 12.5 |

| 4,808 | 50 | 10 | 102 | 220 | 22 |

| 4,809 | 63 | 14 | 226 | 350 | 35 |

| 4,810 | 80 | 18 | 468 | 600 | 60 |

| 4,811 | 100 | 22 | 915 | 900 | 90 |

| 4,812 | 125 | 26 | 1680 | 1300 | 130 |

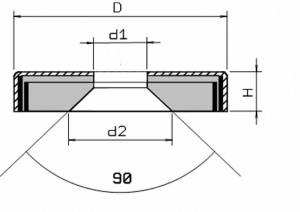

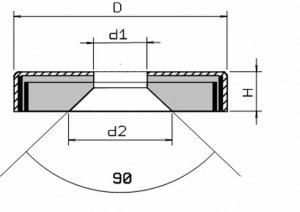

| Item code | D | H | d1 | d2 | g-weight | Force N | Force Kg |

| 04.803C* | 16 | 4.5 | 3.5 | 6.5 | 4 | 14 | 1.4 |

| 04.804C* | 20 | 6 | 4.1 | 9 | 9.4 | 27 | 2.7 |

| 04.805C* | 25 | 7 | 5.5 | 11.5 | 17 | 36 | 3.6 |

| 04.806C* | 32 | 7 | 5.5 | 11.5 | 27 | 72 | 7.2 |

| 04.807C* | 40 | 8 | 5.5 | 12.5 | 52 | 90 | 9 |

| 04.808C** | 55 | 10 | 8.5 | 22 | 85 | 180 | 18 |

| 04.809C** | 63 | 14 | 6.5 | 24.1 | 197 | 290 | 29 |

| 04.810C** | 80 | 18 | 6.5 | 11.5 | 458 | 450 | 45 |

| 04.810/83C** | 83 | 18 | 10.5 | 32 | 444 | 600 | 60 |

| 04.811C** | 100 | 22 | 10.5 | 3. 4 | 815 | 680 | 68 |

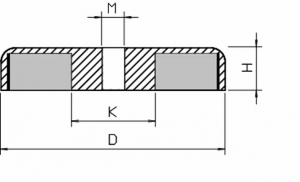

| Item code | D | H | M | K | g-weight | Force N | Force Kg |

| 04.805D | 25 | 7 | 4 | 5.2 | 18 | 36 | 3.6 |

| 04.806D | 32 | 7 | 4 | 5.2 | 29 | 75 | 7.5 |

| 04.807D | 40 | 8 | 4 | 5.2 | 53 | 90 | 9 |

| 04.808D | 50 | 10 | 6 | 12 | 94 | 170 | 17 |

| 04.808DM8 | 50 | 10 | 8 | 12 | 94 | 170 | 17 |

| 04.809D | 63 | 14 | 8 | 13 | 206 | 290 | 29 |

| 04.810D | 80 | 18 | 8 | 14.5 | 240 | 550 | 55 |

| 04.810DM10 | 80 | 18 | 10 | 14.5 | 466 | 550 | 55 |

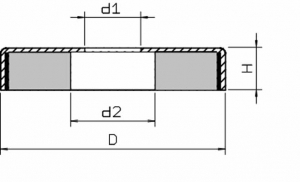

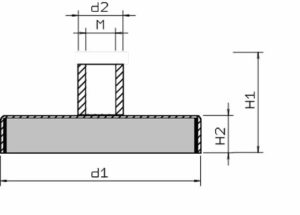

| Item code | d1 | d2 | H1 | H2 | Thread | g-weight | Force N | Force Kg |

| 4,901 | 10 | 6 | 11.5 | 4.5 | M3 | 3 | 4 | 0.4 |

| 4,902 | 13 | 6 | 11.5 | 4.5 | M3 | 4 | 10 | 1 |

| 4,903 | 16 | 6 | 11.5 | 4.5 | M3 | 6 | 18 | 1.8 |

| 4,904 | 20 | 6 | 13 | 6 | M3 | 7 | 30 | 3 |

| 4,905 | 25 | 8 | 15 | 7 | M4 | 20 | 40 | 4 |

| 4,906 | 32 | 8 | 15 | 7 | M4 | 31 | 80 | 8 |

| 04.906/36 | 36 | 8 | 16 | 7.7 | M4 | 42 | 100 | 10 |

| 4,907 | 40 | 10 | 18 | 8 | M5 | 59 | 125 | 12.5 |

| 04.907/47 | 47 | 12 | 20.5 | 9 | M6 | 91 | 180 | 18 |

| 4,908 | 50 | 12 | 22 | 10 | M6 | 111 | 220 | 22 |

| 04.908/57 | 57 | 12 | 22.5 | 10.5 | M6 | 153 | 280 | 28 |

| 4,909 | 63 | 15 | 30 | 14 | M8 | 243 | 250 | 35 |

| 4,910 | 80 | 20 | 3. 4 | 18 | M10 | 499 | 600 | 60 |

| 4,911 | 100 | 22 | 43 | 22 | M12 | 956 | 900 | 90 |

| 4,912 | 125 | 25 | 50 | 26 | M14 | 1720 | 1300 | 130 |

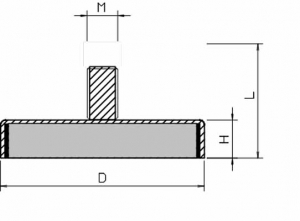

| Item code | D | H | L | M | Force N | g-weight |

| 04.901G | 10±0.2 | 4.5±0.2 | 11.5±0.3 | 3 | 4 | 2 |

| 04.902G | 13±0.2 | 4.5±0.2 | 11.5±0.3 | 3 | 10 | 3 |

| 04.903G | 16±0.2 | 4.5±0.2 | 11.5±0.3 | 3 | 18 | 5 |

| 04.904G | 20±0.2 | 6.0±0.2 | 13.0±0.3 | 3 | 30 | 10 |

| 04.905G | 25±0.2 | 7.0±0.2 | 15.0±0.3 | 4 | 40 | 19 |

| 04.906G | 32±0.2 | 7.0±0.2 | 15.0±0.3 | 4 | 80 | 30 |

| 04.907/47G | 47±0.2 | 9.0±0.2 | 17.0±0.3 | 6 | 180 | 85 |

| 04.908/57G | 57±0.2 | 10.5±0.2 | 18.5±0.3 | 6 | 280 | 146 |

| 04.909G | 63±0.2 | 14±0.2 | 29.0±0.3 | 6 | 350 | 233 |

| 04.910G | 80 | 10 | 23 | 8 | 600 | 270 |

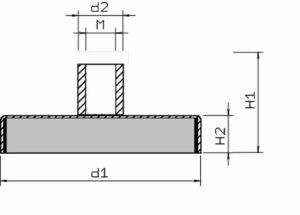

| Item code | d1 | d2 | H1 | H2 | Thread | g-weight | Force N | Force Kg |

| 04.905 STAINLESS STEEL | 25 | 8 | 16 | 7 | M5 | 20 | 32 | 3.2 |

| 04.906INOX | 32 | 8 | 16 | 7 | M5 | 31 | 64 | 6.4 |

| 04.907 STAINLESS STEEL | 40 | 8 | 16.5 | 8 | M5 | 56 | 100 | 10 |

| 04.908 STAINLESS STEEL | 50 | 8 | 18.5 | 10 | M5 | 105 | 175 | 17.5 |

| 04.909 STAINLESS STEEL | 63 | 8 | 22 | 14 | M5 | 228 | 280 | 28 |

| Item code | D | H | d1 | d2 | g-weight | Force N | Force Kg |

| 04.804CINOX* | 20 | 6 | 4.1 | 9.4 | 9 | 22 | 2.2 |

| 04.805CINOX* | 25 | 7 | 5.5 | 11.5 | 17 | 29 | 2.9 |

| 04.806CINOX* | 32 | 7 | 5.5 | 11.5 | 27 | 58 | 5.8 |

| 04.807CINOX* | 40 | 8 | 5.5 | 11 | 52 | 72 | 7.2 |

| 04.808CINOX** | 50 | 10 | 8.5 | 22 | 85 | 145 | 14.5 |

| 04.809CINOX** | 63 | 14 | 6.5 | 24 | 195 | 230 | 23 |

Recent Comments